Credit where credit is due...

I decided I

wanted to have some sort of badge on the car to recognize the

work of Karmann. I did some hunting around and

found this badge for sale online, an early Karmann badge used on

old Volkswagens:

I quickly decided

I didn't want to put the badge outside because I didn't want to

damage the body of the car, spoil the clean lines, or lose the

badge. After careful consideration, mounted it on one of

the blank panels on the dash of the car. I simply removed

the panel surrounding the stick-shift and then the center panel

that houses the reminder light for the passenger-side airbag.

I ordered a replacement part to have on hand since the

installation of the badge involves drilling. There will be

no going back with the part.

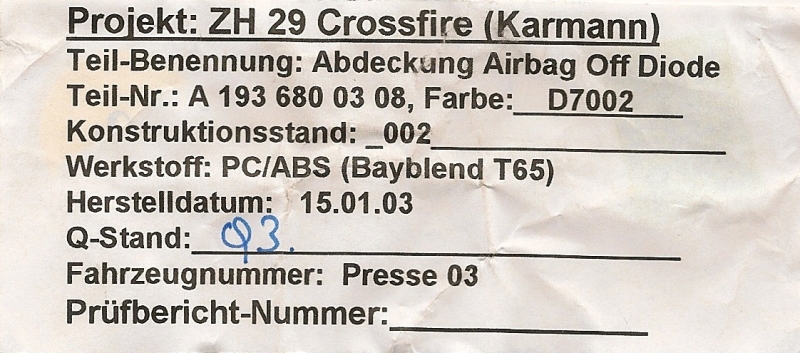

The part came with

an interesting part ticket attached, showing what appears to be

the vehicle designation used internally (Projekt ZH 29). I

found it interesting that the car is designated "Crossfire (Karmann)".

I left the warning light functional but since I never disable the

passenger-side airbag, the light has limited usefulness.

I affixed the

badge using the two pins that are tacked to the back of the

badge and the plastic retainers supplied with it. This

meant drilling two perfectly aligned holes, 1/8" in diameter

into the plastic. I marked the plastic with a center punch

and slowly drilled each hole from back to front. Then I

inserted the pins into the holes and used the retainers.

I asked my

friend who made the

WILLYS

letters to make some KARMANN lettering for me and installed

one set on the car under the wing.

History of the Car Design

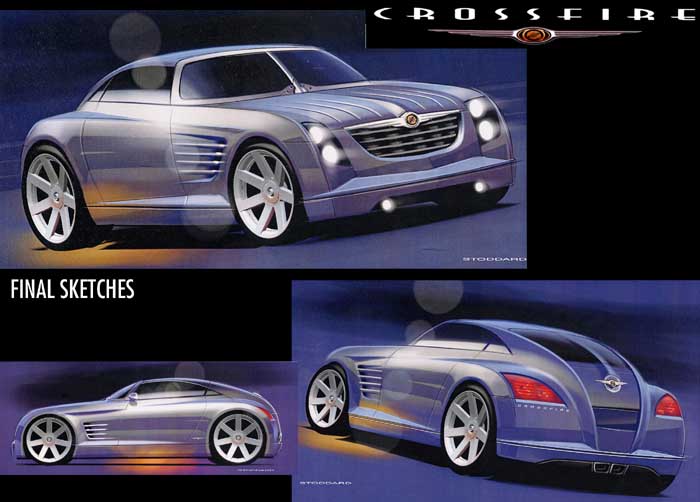

While

researching the history of the car, I learned that the body

design was based on the concept car designed by Eric M.

Stoddard.

In order to

produce the car, the decision was made to use existing

components where possible to shorten the development time and to

leverage existing engineering designs. This led to the use

of a substantial portion of existing parts from the Mercedes SLK.

Indeed, the car is substantially comprised of Mercedes parts and

is very familiar to Mercedes technicians.

When it comes

to the body, Daimler-Chrysler chose to contract the production

engineering and assembly to Wilhelm Karmann Company.

I wrote to the

company thanking them and praising the quality of the car.

They sent to me these items and their regards. (the little car

was not part of the care package)

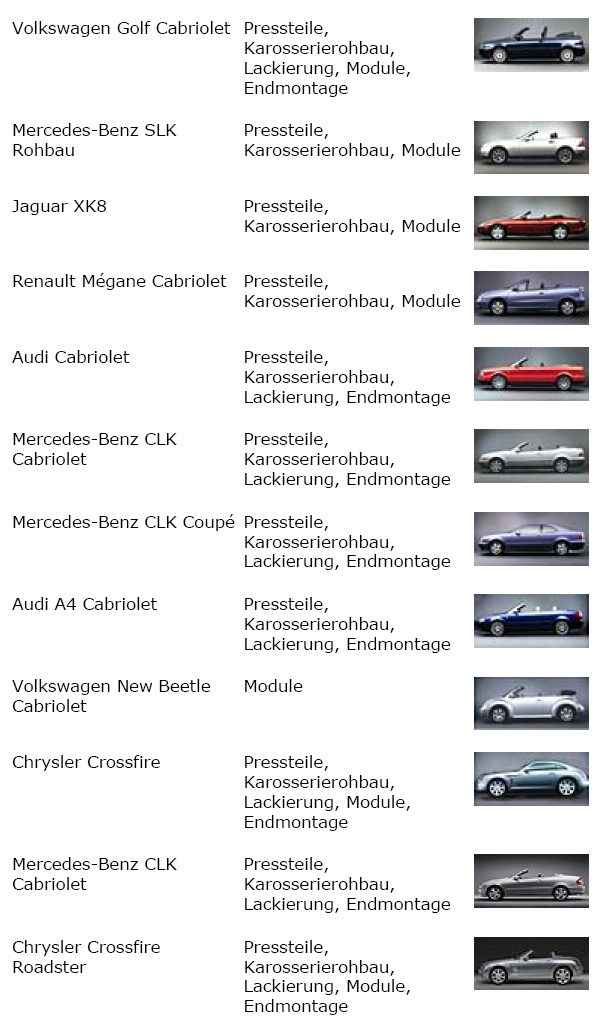

Those familiar

with German cars will recognize this as the company that has

been responsible for several Mercedes-Benz, Porsche, Jaguar,

Volkswagen and several other well-known cars.

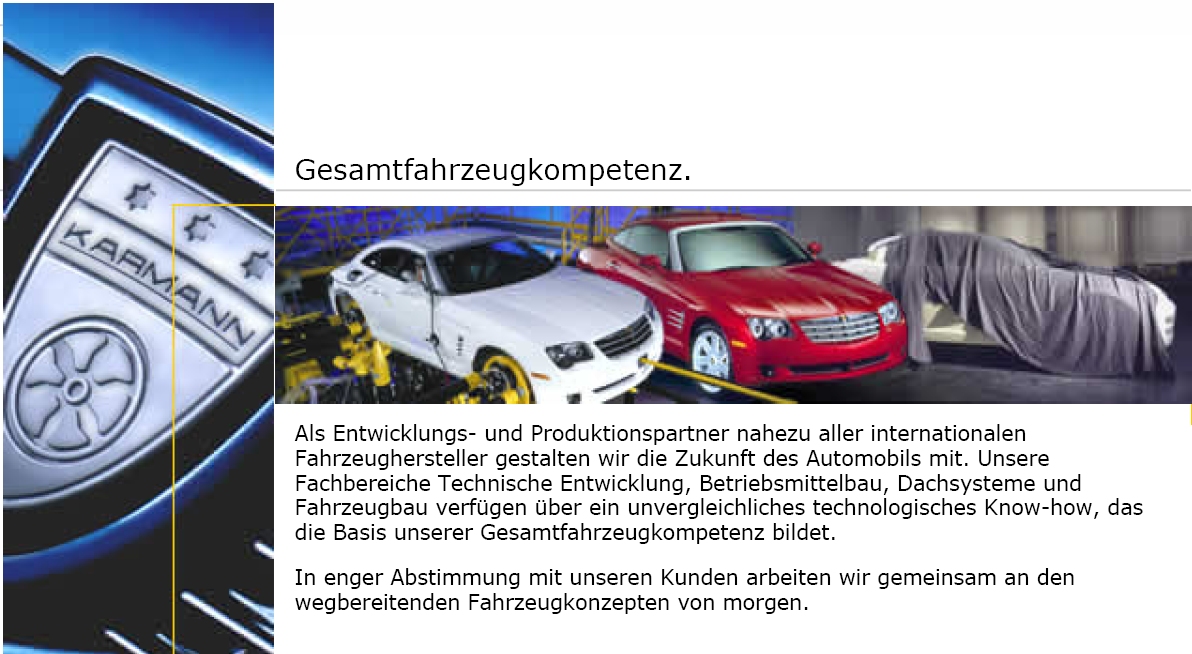

I visited the

Karmann company

web site and was pleased to find that they have a great deal of

pride in their involvement of the production of the Crossfire.

Here is what

Karmann say about themselves:

Computer

Aided Analysis is an important tool in the design and

development process. This method of computer simulation,

used in a projectís early planning phases, contributes

considerably to the economical efficiency of the development

phase.

In early

design phases the analysis of stiffness, modal and crash

characteristics, and the behavior of sealing elements helps

to eliminate inferior design alternatives and to develop the

optimal solution for a product. Fundamental aspects such as

passive safety and crash characteristics are relevant in the

concept phase. Their analysis provides cost-saving benefits

for the subsequent testing and manufacture process. The

results produced by the FEM analysis are extremely reliable

as they are continuously correlated with the data of the

Vehicle Testing Section.

The FEM

Group has its own dedicated computer system and CAE system

support. This support takes care of CAD data

compatibility for a smooth transfer of data to and from our

FEM clients, and it maintains interfaces to Karmannís other

departments.

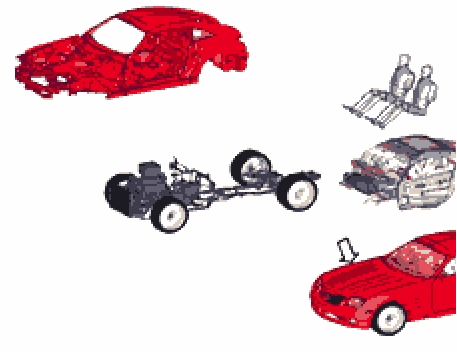

Some

examples of the many types of simulations we can perform:

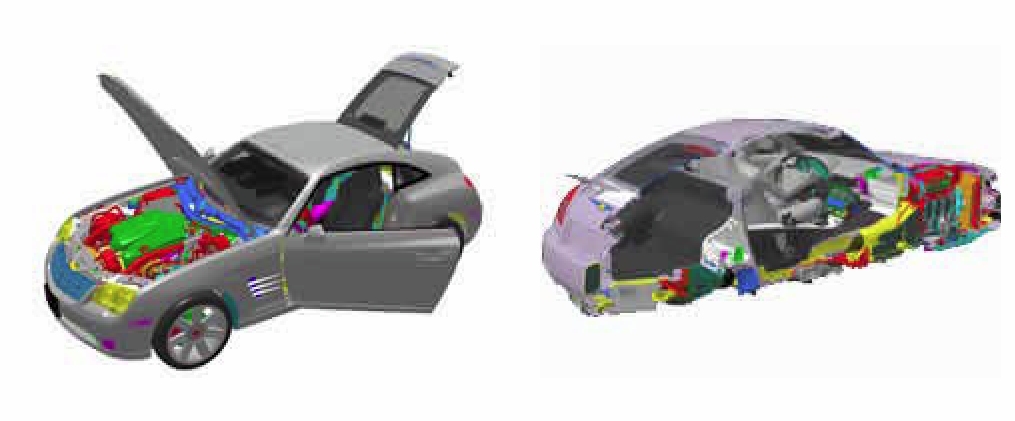

Here are some

of the images depicting various aspects of the Chrysler

Crossfire.

Visitors since

5/17/08