Attributes:

Line Thread Size:M18X1.5

# of Mounting Holes:3

Input Shaft Diameter:3/4"

Output Shaft Diameter:1 1/4

# of Turns Lock to Lock:3 1/16

Type of Hose Ports:O Ring

Additional Contents:O Ring Kit

Pitman Arm Nut: 32~33mm/ 1 3/8"?

Pitman Arm puller: 1 5/16" opening

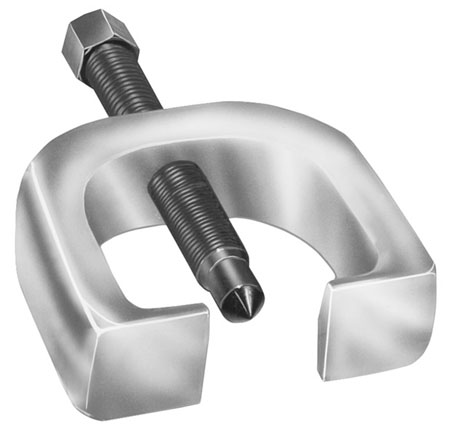

Aside from everyday tools, a pitman arm puller/remover is

needed. I found a couple that would work. I caution that the

one that I got from Napa was a fine tool but it was not wide enough to

fit the Jeep pitman arm. These listed below will work.

OTC 7314A Pitman Arm

Puller

This puller will handle nearly any Pitman arm job on

passenger cars and light trucks. It features special forged jaws shaped

to fit the job, ensuring a positive grip every time. Spread between jaw

tips: 1-5/16"

I removed the

steering box skid plate.

This was simply a matter of removing the nuts and bolt that held it to

the steering box mounting point and front bumper.

Next I removed the

pressure and return lines from the power steering pump reservoir and

drained the fluid that came out into a catch basin. I capped the

openings in the pump. Here's a drawing of the basic components.

6/29/07

I had a little trouble

determining the size of the bolt that holds the pitman arm. I

measured it and determined it to be 33mm or 1 3/8" - both socket sizes

were unavailable at Advance Auto so I grabbed one each 32mm, 34mm, 1

1/4", 1 1/2". The best fit though tight was the 32mm so I used it

to remove the pitman arm nut. I was fortunate that it came free

reasonably easily with a 1/2" long handled drive. I laid on my

back with my feet on the drivers wheel and pulled on the drive more or

less as if I was standing up on the wheel. The tire turned some

until the steering wheel locked into the dash, then the nut came free.

I did soak it overnight with some penetrating oil.

I pushed the rubber

dust seal up off the pitman arm shaft to make room for the pitman arm

puller, fit the puller over the shaft, centering the pin on the puller

pin into the depression on the pitman arm shaft. I left the pitman

arm shaft nut on the shaft a few turns to keep the puller from sliding

off. I tightened the puller, tapped the arm where it goes around

the shaft, tightened the puller some more, tapped some more, tightened,

tapped and soon the arm just eased off the shaft. Again, I had

soaked the shaft in penetrating oil overnight.

I made sure the wheels

were straight before I removed the pitman arm from the shaft, and just

let the arm hang free on the drag link.

I put the nut on the

new steering box together with the lock nut and dust seal and put it

away for the night.

6/30/07

With the pitman arm

out of the way, the rest of the job to remove the steering box went

quickly. Ted stayed with me to help. We removed the bolt

that holds the steering column to the steering box, the three bolts that

hold the steering box to the frame.

With the box supported

by a jack stand I removed the pressure and return lines from the

steering box and we were done (with removal).

Next we sorted out all

the tools and pieces needed to install the new box. I retrieved

the rubber dust cover that slides over the pitman arm shaft, put some

new grease on it, and slide it up onto the new steering box. The

new box came with one of the temporary covers broken off with the

threaded portion in the hole. This was a quick job for an

easy-out. There didn't seem to be any pieces of the plug missing

that could have entered the pump so we continued.

I cleaned up all the

fasteners and hoses. I treated all the nuts and bolts as well as

the line flare nuts with Anti-seize compound. We put the steering

box back in, after first installing new "O" rings and then attaching the lines to

the box, and threading them

back into place under the Jeep. I taped the upper hose ends to

prevent debris from getting inside.

We installed the

steering box by attaching the steering column to the input shaft.

There's a flat spot that lines it up. Then I got the frame bolt

holes lined up and the bolts installed. Then I installed the

pitman arm. Finally we reconnected the upper lines.

There are several

documented ways to fill and bleed the steering box. Since I did

not have a catastrophic failure (steering gear parts circulating through

the system) and the pump didn't fail, I felt I could top up the fluid

and be done with it. That still required that I fill the

reservoir, cycle the steering wheel back and forth several times (all

with the engine off and the front wheels off the ground to make it

easier). I repeated filling, cycling until no more fluid was

required to fill the reservoir to the "cold" mark on the cover stick.

Then I turned on the

Jeep and ran the steering back and forth a few more times and turned off

the vehicle. It took very little fluid. I started the

vehicle and let it run while cycling the steering back and forth with

Ted watching for leaks. We checked for leaks at the reservoir

pressure and return, at the steering pump where the pressure and return

lines connect, and the pump itself. Dry as Death Valley in summer.

The steering gear made

no untoward noises and the steering worked fine. Mission complete!

The biggest part of this job was getting the correct puller, fluid,

socket, the part itself. Once the difficult job of sourcing and

pulling was done, it was just six fasteners!

After the Jeep sat for

several hours while I reinstalled my

winch and refinished winch plate, I started it up and winched it up

my driveway to tension onto the winch spool the cable that had been

removed when I sent the winch out for service. I let the Jeep run

while I did this to keep the battery charging. When it got to the

top of the drive, I let it sit running while I finished wrapping the

cable to store. When I got done I noticed a small drop of

something on the pavement precisely under the same spot as the leak I

had done the job to fix! I pulled the Jeep up to take a look and

found the steering was hard! Great. All this and it still

was bad!

I shut off the Jeep

and looked at the fluid in the reservoir. It had lots of little

bubbles in it. So I let it sit for about 10 minutes while I took a

look at the service manual to see if I could diagnose the problem (from

a selection of several defects listed for the pump or box). All

the symptoms I had pointed to two primary causes - not enough fluid or

low tire pressure.

Wanting the easy

answer these choices sounded good but I remained skeptical. I went

back out and cycled the steering through several back and forth motions

again. The fluid went down a surprising amount but no more leaking

showed. I topped up the reservoir, started the Jeep and ran the

steering back and forth some more. I shut off the Jeep and checked the

fluid. There were no bubbles and the fluid was staying up.

The steering felt fine though tighter than I remember. But since I

have been driving our Cherokee and Commander for the last several weeks

during all this restoration work, I wondered if perhaps I was comparing

the feel to a faulty memory.

I checked the tire

pressure and found it was down by about 12psi on all four tires.

So the combination of air in the system and low tire pressure was indeed

the likely cause of the stiff steering. The manual was right.

I took the Jeep out to return some unused sockets and run some errands.

At each stop I checked the fluid. No bubbles and only a slight

drop in level. When I got home I filled the reservoir up to the

mark. Should be good to go - finally...

Visitors since

6/30/07