Most times

I have gone out on trips with my full doors. Quite often the

internal struggle whether to bring them or not would go something like this:

"It's

not supposed to rain."

"Yeah,

but what if it does - it's two hours on the road and it will really

stink if it's raining and the doors are leaning against the wall in the

garage and not on the Jeep!"

Or I

would go out for an overnight trip and decide to remove the doors,

but be forced to leave them in camp. This wasn't nearly as

problematic (though it did sometimes result in later wishing I had them

along) but I always had the nagging fear they'd be gone when I returned.

Anyone who's priced full steel doors from Jeep lately knows that the

insurance company would not be very happy to hear from me, and I would

not be very happy with either the cost of replacing them myself or

paying the surcharge on the insurance.

So most

of the time I just left the doors on, sometimes happy I did when the

weather turned, but often wishing I had half doors that I could stow on

board and use them only when needed.

I looked

at two options to solve this problem and had decided that soft upper and

lower doors would work. But when I got my new sailcloth top, it

came with new door uppers. That was nice except that I didn't have

the lowers and these would only fit on the hard lower halves.

Pricing just the lower soft doors, I found they were not made to accept

uppers. It's a great example of bad engineering, or good marketing

- making the uppers so that are dedicated to just one solution and not

both, but such as it was, I decided to scare up some upper door frames,

mount the new upper skins and stow them away for the day when I got some

lower half doors to use them with. The door frames were cheap so

it was not a big investment.

I found

some steel half-doors online and had made arrangements to get them but the deal

fell through. I watched regular steel half doors sell all day long

on eBay for $600 or more.

I even refinished a set for my friend Carl.

By the time I got through all this suffering, I pretty much decided

there was nothing I could do but sell the uppers and buy what I needed.

Then I

found the perfect solution.

Warrior Products makes a half door

that is compatible with my soft uppers. So after staring at them

in the catalog all winter long, I finally bought them.

I chose

to get the black ones and the brackets required to install the uppers.

But that's just the beginning...

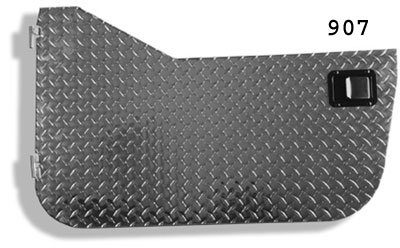

Warrior Products Diamond Plate Half Doors in Black for 97-06 Jeep

Wrangler TJ

(Quadratec Part No:

11140.02 326.04)

These are the

doors we installed on the 1999 Wrangler (picture may not match the product

color)

Warrior Products Window Brackets for Diamond Plate Doors for 97-06 Jeep

Wrangler TJ

(Quadratec Part No:

11140.900 51.84)

They

came very quickly and I got busy deciding what I was going to do with

them. They are cut from diamond plate aluminum and are powder coat

black.

They are

quite minimalist. The thinking is this - the full doors I have are

large, heavy and cannot be removed on an outing unless they are left

behind somewhere and retrieved later. This presents two problems. First,

storage in a secure location to prevent damage and theft, and second I

take a calculated risk if I leave home without them and encounter cold

or wet weather and need them. Overall

I am pleased with them though in their minimal state I needed to

engineer and install several items to make them useful:

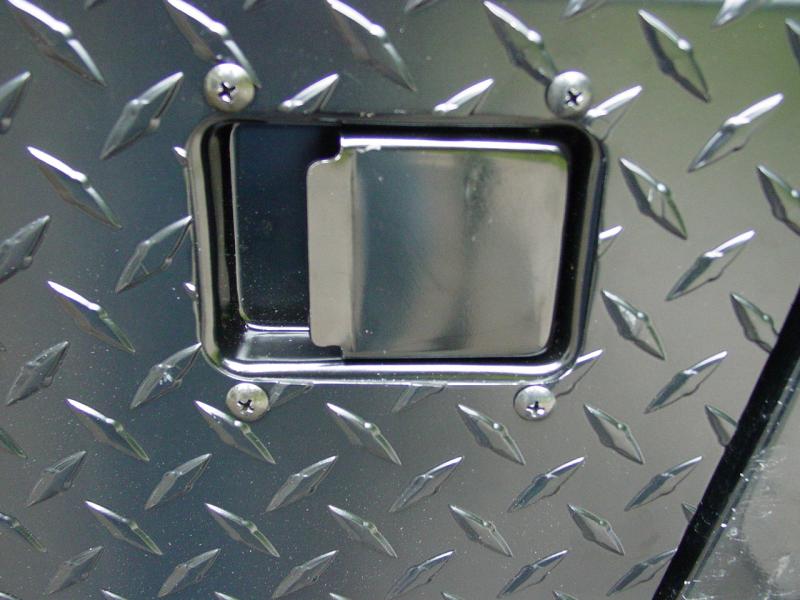

Latches

The

doors come complete with latches. They're not very impressive in

terms of their life expectancy but they'll have to do until I can find

something better. I would recommend treating them well if you want

them to last.

I

installed them on their respective doors using the provided hardware.

More about hardware in a little bit...

The

latch has an angle to the catch that conforms to the shape of the door

opening.

The

instructions are very vague but it appears from the way the door panels

fit on the Jeep and the contour of the panels that the latches are meant

to be installed with the plate outside the door panel. That is how

they're shown in the factory photos. But with the added thickness

of the weatherstripping I used, I installed them on the inside of the

door panel.

Installing the latches is pretty straightforward. The holes are

drilled in the door panels and aside from specific parts for left and

right (they're labeled in case you can't tell), there's not much to

tell.

Doors | Upper Doors |

Hardware | Weatherstripping |

Mirrors | Check Straps

| Storage Bins

These are the

doors we installed on the 1999 Wrangler (picture may not match the product

color)

Soft

Upper Door Panels

The new

doors are designed to take an upper soft panel with plastic window,

and break down into two pieces each. These are small enough to stow on

board and thereby provide a way to bring them along collapsed or in

place and remove or install them as needed without retrieval from remote

storage.

I got

the hard bottoms rather than the fabric because I already had the soft

uppers (that came with my soft top) and this was the only combination that

would work given what I had on hand. I pulled out my brand new

soft uppers that I had assembled two years ago and was done with this

step, except for mounting the brackets that hold them!

Soft

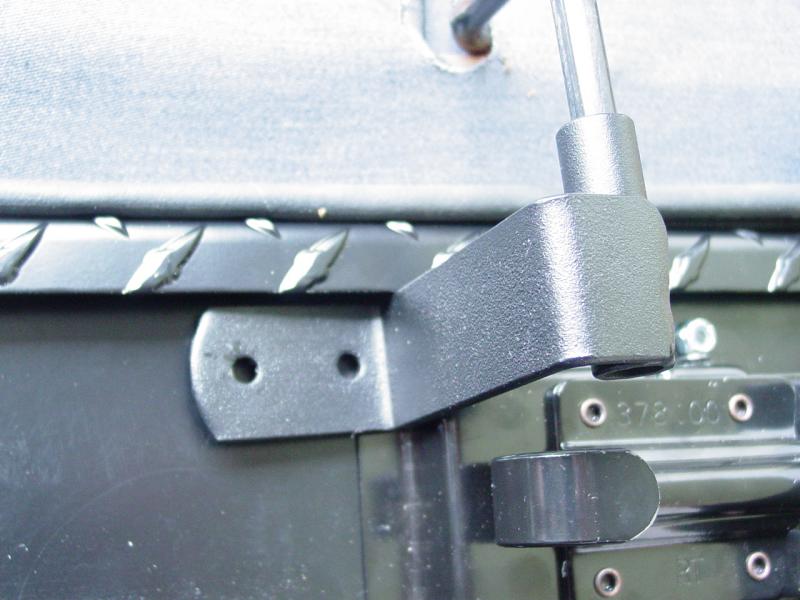

Upper Mounting Brackets

These are the

doors we installed on the 1999 Wrangler (picture may not match the product

color)

These

were sold

separately. These provide the

necessary hardware to hold the upper doors in place.

Mine

came inside a separate box with no instructions of any kind. The

doors are not marked or drilled (no surprise since some folks won't

order these brackets and would not want holes or marks). This

leaves those of us who do want upper door brackets to locate and install

the brackets, with some holes to drill.

First, I

put the doors on the Jeep and held the upper doors in place to see what

took shape. I compared the images in the catalog that shows the

brackets installed to see if it matched what I was seeing.

It did,

and it helped me to orient the brackets properly. There are six

different brackets - three for each side, and they only work in one

position. So it took a few minutes to sort that out. I

believe the instructions would have provided some insight here.

|

|

|

Bracket

1

Right Front |

Bracket

1/2

Right Middle |

Largest

Bracket

Right Rear |

I

aligned the upper door panel so that the edges of the panel (side to

side) matched the door panel. I pressed the rubber seal on the

bottom edge of the upper door down hard up against the upper part of the

lower door. With the brackets placed as shown on the support pins on the

upper door, I got the brackets aligned.

When I

felt sure the brackets were in the right positions (I checked both doors

to make sure I was not using the wrong brackets), I used a paint pen to

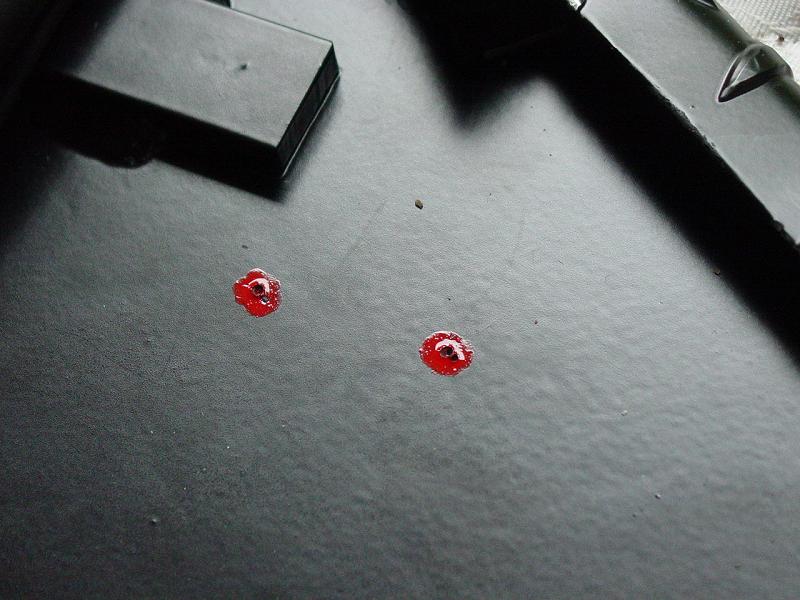

mark the exact spot that I would drill out.

It is

important to check these marks after each bracket is laid out to be sure

that the upper door has not moved and the other brackets still match

their markings.

Next, I

used a center punch to place a dimple in the center of each mark to help

keep the drill bit from sliding around and missing the mark.

The

value of this step cannot be overstated. It is much easier to

drill in the right spot if the drill bit does not move around. One

of the holes centers on the very edge of the door latch.

Getting

that hole right without the center mark to keep the drill in place would

be nearly impossible. Go buy a center punch if you don't have one

- working with metal requires it!

Be sure

you have the exact-sized drill bit to make a hole that perfectly fits

the brackets. This will assure that the brackets cannot move

laterally and with the fastener tightened properly will not move away

from the door panel. With the amount of pressure that is put on

the upper door panel to keep it tight against the door opening, you want

to be sure you get this right so that door panel does not wobble around.

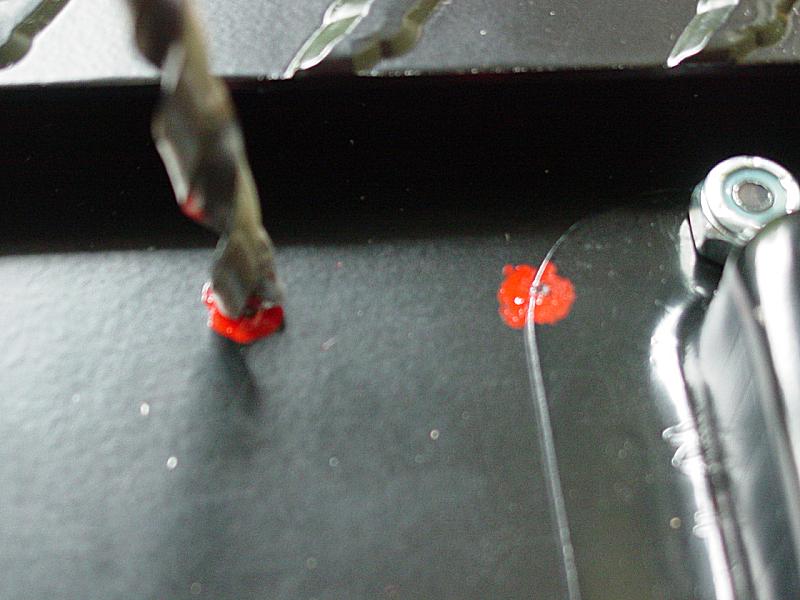

Centering the drill bit on each punch mark, drill the holes. This

image was staged to show centering the bit - be sure to drill with a

wood block you don't care about behind the panel, and with the drill bit

perpendicular to the door panel... The material is very soft and

will not take much to drill through.

Two

holes done...

Doors | Upper Doors |

Hardware | Weatherstripping |

Mirrors | Check Straps

| Storage Bins

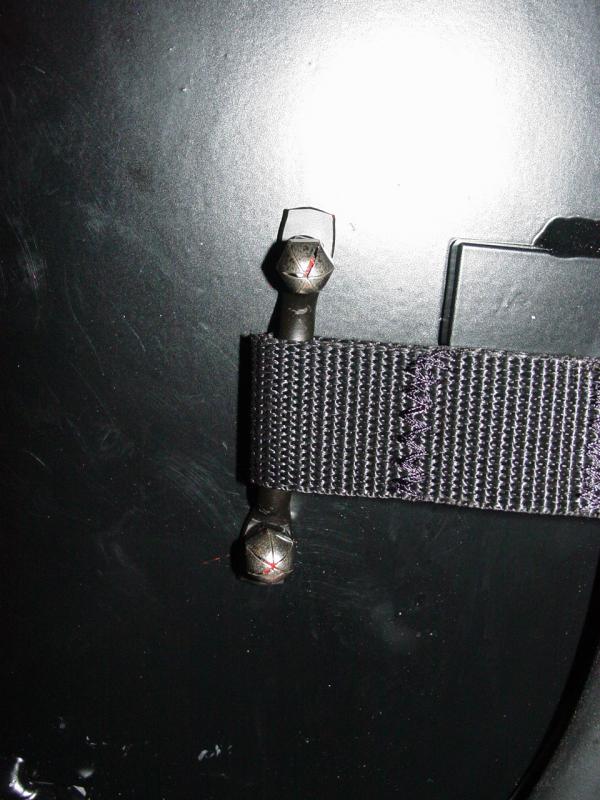

Fasteners (Nuts, Bolts and Washers)

The

hardware included will work just fine, but if you want to dress up the

installation like I did, consider using stainless steel button head fasteners,

and acorn nuts. I test-assembled the brackets with the provided fasteners

and replaced them with the button head fasteners as soon as my order

from Bolt Depot arrived.

I used

Thread Locker Red to make sure the bracket fasteners would not come

loose until I want them to - and using Red probably means I will be

breaking the fasteners off to replace them with Button Socket Head Cap

bolts (stainless steel).

I put

one extra washer under the bracket mounted next to the latch to make up

the thickness of the latch under the other side of the bracket.

Each bolt got washers on the outside of the door and three on the inside of the

door to allow the acorn nuts to properly tighten down. This distributes the load of the bolts wider on the door

panel and protects the passengers from getting cut on the bolts.

Socket Button Head

The

improved hardware I purchased does several things. It makes the

fasteners less prominent, less prone to rust, and more attractive.

The acorn nuts I installed inside the door covers the end of the bolts

reducing the risk of injury from hitting the bolt, and is more

attractive. They also match the ones on the

Sun Performance Heavy Duty Rocker

Protection and the Sun

Performance Lamp Protectors...

|

Part Number: |

92949A540 |

|

Head Style |

Button |

|

Material Type |

Stainless Steel |

|

Finish |

Plain |

|

Class |

Not Rated |

|

Stainless Steel Type |

18-8 Stainless Steel |

|

Drive Style |

Hex Socket |

|

Thread Size |

1/4"-20 |

|

Length |

3/4" |

|

Hex Key Size |

5/32" |

|

Thread Style |

Right Handed |

|

Thread Length |

Fully Threaded |

|

Head Diameter |

.437" |

|

Head Height |

.132" |

|

Rockwell Hardness |

B85 |

|

Minimum Tensile Strength |

85,000 psi |

|

Thread Fit |

Class 3A |

|

Specifications Met |

Not Rated |

|

|

| Factory

Hardware - Good |

Replacement Hardware - Better |

Here are the brackets bolted on (inside door panel view).

These are the

doors we installed on the 1999 Wrangler (picture may not match the product

color)

Here are

some pictures showing a second test fitting of the passenger door.

These were taken after a test drive to see how well they sealed and fit

the opening. The stock fasteners will still installed and I had

not yet installed the mirrors. I was even blessed with some rain to test how well

they keep the wet out!

A look

at the inside of the door when mounted on the Jeep.

|

Door Upper

Bracket Assembly to Door |

|

Quantity |

Part |

Size |

Number |

|

12 |

Acorn Nuts |

¼-20 |

Hillman

#882034 |

|

48 |

Flat

Washers |

¼ |

Bolt Depot

#05323 |

|

12 |

Socket

Button heads |

¼-20 x ¾ |

Bolt Depot

#4412 |

|

12 |

Hex Nuts |

¼-20 |

Bolt Depot

#2563 |

Doors | Upper Doors |

Hardware | Weatherstripping |

Mirrors | Check Straps

| Storage Bins

Stock Product

At this

point the stock assembly is done. Here is what it looks like.

Admittedly the Jeep is dirty but this image shows the doors with the

manufacturer-supplied hardware and prior to installing mirrors, check

straps and other customizations and hardware upgrades.

Doors | Upper Doors |

Hardware | Weatherstripping |

Mirrors | Check Straps

| Storage Bins

Weather Stripping

The 1/8"

x 1/16" material they included is laughable. I'm not sure what kind of

weather it's supposed to keep out, but it was not satisfactory to me. I

purchased some OEM material that will provide damping and

weather sealing properties - $40 added to the cost of the doors.

But the difference it makes is huge.

Weatherstripping Installation

Following the manufacturers instructions, I cleaned the surface on the

doors where the weatherstrip would go with isopropyl alcohol. Do

not underestimate the importance of this step. The high-tech

adhesives used for automotive products work very well, but only if the

surfaces to which they are applied are spotlessly clean and free of

dust, dirt, water and grease. Isopropyl alcohol does an excellent

job of removing these things quickly. Don't skip this step or your

weatherstrip will fall off the doors in short order.

After

cleaning the door surfaces, I removed just a little of the protective

liner on the weatherstrip, then I lined up the start of the weatherstrip so that it started

under the folded down top edge of the door. This will help protect

it from being caught by passengers entering and exiting the vehicle.

Then I

slowly worked my way along the edge of the door, lining up the

weatherstrip just inside the edge of the door, then slipping more of the

protective liner out as I lightly pressed the weatherstrip in place.

Working

with the weatherstrip, unrolling with the curve following the same

general curve of the door, made it easier to work and probably increases

the chance it will stay stuck because the rubber had already started to

take shape after being stored in the roll from the factory to the store

to me. I continued applying the weatherstrip until I reached the

hinges.

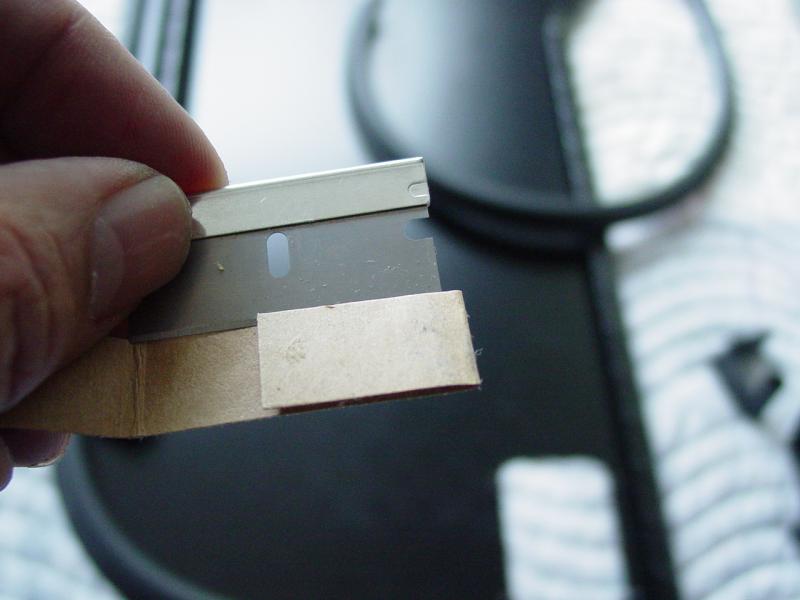

At this

point I retrieved a new single edged razor to cut the weatherstrip.

But

instead of either just running over the hinge bar which would have left

gaps and caused the weatherstrip to be thicker here, I cut into the

weatherstrip just

enough to allow the adhesive to lay flat on the hinge bar and conform

down to the door surface, but without cutting the weatherstrip surface

that provides the seal.

This

should give a better seal and allow the weatherstrip to remain stuck to

the door. Here is a shot showing the finished seal.

At

first, this is going to make the doors harder to close. But as the

weatherstripping conforms to the opening and loses some of its newness,

it will allow the door to close more easily and still maintain a seal.

Manufacturer

Instructions for Installation (not all info applies - we

did not have any old weatherstrip to deal with)

3M Part Number

08650NA EPDM Rubber Weatherstrip

7/8 thick by 3/4 inch wide x 8 feet long

http://www.3m.com/

Simple application procedure

This

supplemental weatherstrip applies quickly and easily

next to damaged weatherstrip.

For best adhesion,

application surface must be clean and dry. Remove

dirt, grease oil etc. from surface with 3M Brand

Adhesive and Wax Remover, (3M part #3607 or #08984) or

isopropyl alcohol. Dry surface completely. Recommended

application temperature range is between 60°F (15°C) and

100°F (38°C).

Note: DO NOT REMOVE EXISTING DAMAGED WEATHERSTRIP!

To apply: measure and

cut desired length of weatherstrip; remove the orange

liner (avoid touching adhesive side with fingers or

thumbs), and lightly press in place

next to damaged weatherstrip.

DO NOT over-stretch weatherstrip.

Immediately check

alignment and reposition as necessary. When properly in

place, secure by pressing firmly along entire length of

the weatherstrip. It's that simple!

|

Doors | Upper Doors |

Hardware | Weatherstripping |

Mirrors | Check Straps

| Storage Bins

Rearview Mirrors

I have

left-over right and left factory mirror mounting plates from the

spare mirrors that I use when doorless.

I mounted them in

the proper place on the doors. The plates mount with flat socket

head cap bolts and self-locking nuts. Instead

of relocating the factory mirrors, I bought two small Harley-Davidson

Mirrors that will easily collapse for storage. The installation of

the Harley-Davidson mirror mounting the factory brackets is mildly

custom since the hardware is not a perfect match. Here is what I

did.

I

purchased an assortment of hardware and special fittings from a local

Lowe's, and also from Bolt Depot. The stuff I got at Lowe's is

quite common; the stuff I got at Bolt Depot is less common. I have

listed the parts, sources, quantities and sizes below. All the

hardware except for the nylon spacers is 18-8 stainless steel.

In order

of assembly working from right to left in the image above:

-

Fender Washer

-

Rubber Washer

-

Spacers (2)

-

Rubber Washer

-

Metal Washer (part number not listed, from home parts bin, but a

critical item, fits inside bracket)

-

Tapered spacer (included in Harley-Davidson mirror kit)

-

Nut

(acorn nut shown, used lock nut also supplied with mirror kit)

-

The

fender and rubber washers are slipped onto the mirror arm, then the

arm is inserted into the bracket (the opening of the bracket faces

downward).

-

The

two nylon spacers are slipped inside the bracket and onto the mirror

arm.

-

The

other rubber washer is inserted inside the bracket and onto the

mirror arm.

-

The

metal washer is inserted inside the bracket and onto the mirror arm.

-

The

tapered spacer is inserted inside the bracket and onto the mirror

arm, centering itself into the hole on the washer - this centers the

bottom of the mirror inside the bracket.

-

The

nut is inserted inside the bracket and threaded onto the bottom of

the mirror arm. It will just thread to the point where the

bottom of the mirror arm is flush with the shoulder of the nut.

The top washer outside the mirror bracket will become slightly

concave, indicating a good tight fit.

The

bracket is mounted to the doors at the very top leading edge. This

causes slight interference with the bolts that hold them on and the

hinge bracket. I used a hand grinder to produce some clearance.

91875-82TA - Right

Side

91892-82TA - Left Side

Flat Socket Head

Bolts for mounting bracket

|

Part Number: |

92210A542 |

|

Head Style |

Flat |

|

Material Type |

Stainless Steel |

|

Finish |

Plain |

|

Class |

Not Rated |

|

Stainless Steel Type |

18-8 Stainless Steel |

|

Drive Style |

Hex Socket |

|

Thread Size |

1/4"-20 |

|

Length |

1" |

|

Hex Key Size |

5/32" |

|

Thread Style |

Right Handed |

|

Thread Length |

Fully Threaded |

|

Head Diameter |

.531" |

|

Head Height |

.161" |

|

Rockwell Hardness |

B70 |

|

Minimum Tensile Strength |

70,000 psi |

|

Thread Fit |

Class 3A |

|

Specifications Met |

Not Rated |

|

Mirror

Assembly to bracket and door |

|

Quantity |

Part |

Size |

Number |

|

2 |

Fender

Washers |

5/16 x

1-1/4 |

Hillman

H#880345 |

|

4 |

Rubber

Washers |

5/16 x

1-1/4 x 1/16 |

Hillman

H#880375 |

|

6 |

Socket

Flat Head Bolts |

¼-20 x 1 |

Bolt Depot

#4484 |

|

4 |

Nylon

Spacers |

1 x 3/8 x

3/8 |

Hillman

#880448 |

|

6 |

Lock Nuts

Nylon Insert |

¼-20 |

Hillman

#882040 |

Doors | Upper Doors |

Hardware | Weatherstripping |

Mirrors | Check Straps

| Storage Bins

Edging

The

doors are cut from flat stock and while the edges appear to have been

burnished to remove sharp edges and burrs, they're still a bit sharp and

unfinished looking. $2 worth of 1/4" vinyl tubing and $5 worth of

industrial adhesive should give me a nice black edge (cut the tubing

neatly to create a channel, then glue it on) I will write this up

when I have finished doing it.

Inside Door Panel Lining

The

inside of the doors are simple flat metal plates with the top edge (the

window sill, if you will) simply rolled over to form a ledge. Three

brackets (sold separately) bolt to the metal door to accept the upper

door mounting pins. The pins simply insert to the brackets. This leaves

the three brackets and the three pins exposed to the interior and

looking like a great place to get raked should I abruptly be forced into

the door during a crash or sudden stop (seatbelts and airbags

notwithstanding). So I am planning to cut some material (wood or

plastic) to countersink these brackets and form a ledge that will

double as an arm rest, while putting the brackets safely below a smooth

surface that would be less risky to rub against.

Inner

Door Panel

One

detail that is vexing is the inner surface of the door

plate. I checked price for sound deadening material. HiFi material

for doors was prohibitively expensive ($100 for a package of

self-adhesive rubber tiles with fancy metallic logo-clad exposed

surfaces); weather guard roofing (used for the roof-edge near the gutter

to protect against frozen water from rotting the roof deck) which was a

relative bargain in terms of price ($59) and quantity, but still too

expensive and textured like roofing shingles, which was unacceptable.

The one thing left that might work is the material used to seal

stand-alone constructed showers - a self-adhesive, rubber material in

thick sheets - but I got distracted at the home supply store and

neglected to price it. Stay tuned...

Doors | Upper Doors |

Hardware | Weatherstripping |

Mirrors | Check Straps

| Storage Bins

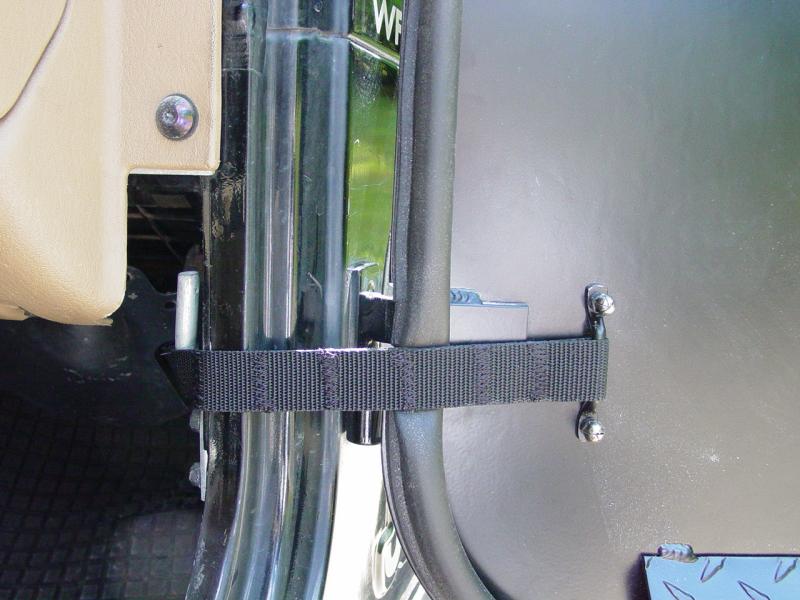

Check

Strap

Two more

things actually - the catch-strap that keeps the door from

swinging wide open and hitting the Jeep. I need a couple pieces of

webbing and a couple footman loops. On order...

|

|

|

Footman Loop and Finish Nuts |

Button Head Stainless Steel Allen Bolts |

|

1

13029+00 Smittybilt (769401) ADJUSTABLE DOOR CHECK STRAPS (PAIR) 12103.01 $7.99 $7.99

2

23017+102 KENTROL FOOTMAN LOOP 55-86 CJ SS BLACK 50423 $3.99 $7.98

Inside Handle

I may

add some sort of loop handle to use to close the door from inside

as there is no handle or grip of any kind. Presently I use one of

the legs of the upper soft door as a handle to latch the door from

inside.

Dome

Light shut off

The pin

that activates the dome light switch is not activated by the doors.

I may add a tab that will shut off the dome light when the doors are

closed. I can use

the switch I put in but this would disable the

key and light warnings that have proven so useful to me in the past.

Doors | Upper Doors |

Hardware | Weatherstripping |

Mirrors | Check Straps

| Storage Bins

Storage Bins

I wanted some pouches for

storing the stuff I keep on my doors. I found a couple Back Seat Storage bags that

looked like they might work as storage on my half-doors.

So I purchased them and

brought them home. On the way, I picked up some larger stainless steel washers.

I took off the acorn nuts

on two of the bolts that hold the brackets in place. I made holes in the bags to go

onto the bolt, then glued a washer on each side of the hole in the bag to provide strength

to the bag where it is bolted to the door. Then of course, I bolted the bags to the

doors.

I put them so they'd

remain below the top edge of the door even when the door uppers are removed.

Here's what it looks like with the uppers

off...

The passenger side...

With the uppers installed...

Doors | Upper Doors |

Hardware | Weatherstripping |

Mirrors | Check Straps

| Storage Bins

Summary

It will

take lots of details to work before it is done, but this is an

interesting project. What will be funny is when people see them and like

them so much they go purchase them and then find out what really comes

out of the box! To finished all the modifications described here,

plan on spending another 25-30% of the cost of the doors on the upgrades

described here. And that does not include the soft upper door

frames and coverings! In the end it's not much cheaper than some

used 1/2 doors that need to be painted or the Bestop plastic doors that

come with speakers. But these doors can be stashed on board if you

don't need them and this was the primary reason for choosing this

approach. If you don't want to remove your doors while you are on

the road, those options are probably a better value proposition for you.

Comments

A kit of

the upgrade stuff would make an interesting product. It it does

disappoint that the manufacturer would not have thought of it and

offered it as an option.

Also I

will probably replace all the hardware with Allen head stainless button

fasteners to stay consistent with the other fasteners used on things

bolted to the Jeep so far.

A nod to

style I guess...

Doors | Upper Doors |

Hardware | Weatherstripping |

Mirrors | Check Straps

| Storage Bins

Chrome Won't Get You Home

I've heard it said many

times, and it's true. Words to live by...

Doors | Upper Doors |

Hardware | Weatherstripping |

Mirrors | Check Straps

| Storage Bins

These are the

doors we installed on the 1999 Wrangler (picture may not match the product

color)

Visitors Since

5/27/2006