With the annual

inspection due in a few days, and the odometer nudging 195,700 miles, I

took on the job of attending to a few things that needed to be taken

care of. There were a couple burned out marker lights, the

brakes

were wearing thin, it was time to rotate the

tires, and I decided to

change fluids, filters, and do an ignition system tune up.

So after breakfast I

made my list of parts. I decided I would try some aftermarket

parts. Partly to save some money over the cost of dealer parts,

and partly to save the 70-mile drive to the dealer. With my list

complete, I headed out the door for the nearest

NAPA Auto Parts.

I picked up all the

parts with the exception of the dielectric grease, wiper refills and

side marker bulbs. I asked if they gave Jeep clubs discounts and

the counter guy looked at me like a deer in headlights. But he

offered that AAA customers get discounts so I produced my card and saved

about $70 on my $260 order. Not too shabby!

With everything bought

and paid for, it was just a matter of taking it home and installing it

all.

Ted stayed home to work

with me while Tom and Maria went to a 5-year-old's birthday party.

We had to talk Ted into staying but pretty soon he was interested in

helping me.

I started with the easy

stuff. I removed the drain plug on the oil pan after laying out

pads to lie on and a basin to catch the oil. While the oil drained, I removed the old oil filter and

replaced it with a new one.

Then I replaced the air

filter. The new FRAM air filter no longer has gray foam pad that

goes underneath the filter so I saved it from my old filter, washed it

out and glued it onto the new filter with narrow beads of silicon cement in the same

position as found on the old filter.

Ted finished getting

dressed for the weather, a "balmy" 40-degree winter day with no sun. I replaced the

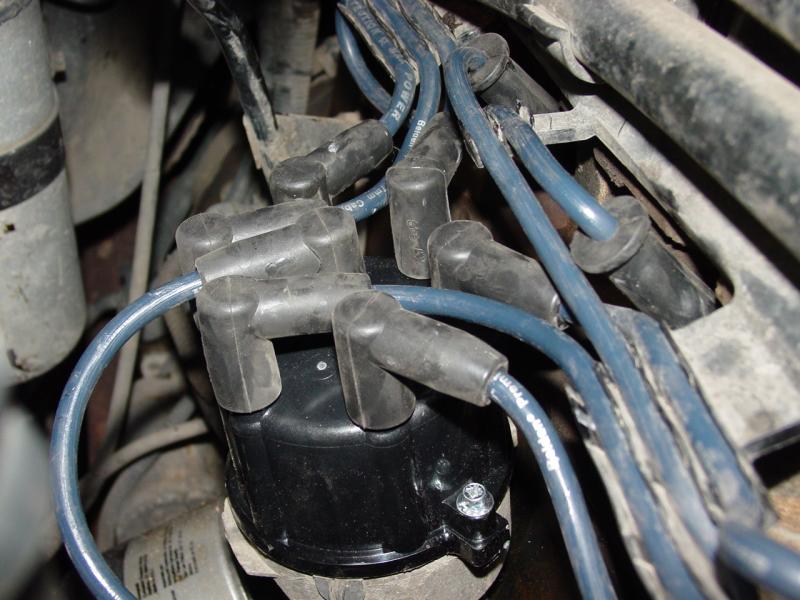

spark plug wires one by one and laid them loosely on the old plugs and

rotor. Once all the new plugs were routed I replaced the plugs.

The plug closest to the firewall was a bit tight and the one closest to

the front of the engine a bit hard to get to, but I got them all off

without much drama. I explained to Ted what I was doing and the

logic of doing one wire at a time and comparing the old wire to the

selection of new wires. While a basic approach to replacing

ignition wires, it makes it easy to keep things straight and also

confirm that the correct replacement wire set is in hand.

I had previously gapped

the plugs (.035) and put a little anti-seize on them. I installed

them one by one and then put the dielectric grease on them before

pushing on the spark plug wires. I gave Ted the job of verifying

the gaps and he managed to find two that were a couple thousandths off.

So I showed him how to gap them and explained why it was important.

When all the plugs were

installed I swapped out the cap and rotor. Ted asked questions

about the operation of the distributor and I demonstrated with the old

parts, showing how the distributor rotor makes contact with each anode

in the distributor cap, and in turn the power goes down the wires to the

plugs.

Then I closed the oil

pan and poured in the new oil. There was some oil that had spilled

out of the old filter and drained along the engine skid plate and found

its way to the mats I put down to lay on. So I cleaned that up and

showed Ted where it came from and explained that we needed to get it all

off the skid plate so that it would not keep dripping and soil the

ground. I also explained that if we left it we might confuse it

for a leak. The easy stuff was done.

Next I jacked up the

driver's side and removed the front tire. Ted ran the floor jack

and got lessons on proper placement of the lift point. He was very

helpful all the way through the job. Next I removed the brake

caliper and rotor and replaced the rotor and brake pads. This was

more or less straightforward, the only part of the job that was tedious

being the pushing of the caliper piston back in while recovering the

excess brake fluid from the reservoir. I took

the opportunity to hit the grease zerks too.

Then I

jacked up the driver's side rear tire with the front still up on jacks.

This allowed me to rotate the tires front and back. I gave Ted the

job of removing the loosened lug nuts and lining them up to be cleaned.

We also talked about changing tires and the proper order to loosen

(before jacking) and remove (alternating lugs) lug nuts. We also

talked about how the tires and wheels are heavy and can come loose once

the lug nuts are removed. We even had a demonstration of what can

happen when the jack stand is not placed properly - the front suspension

unloaded a little on top of the jack stand causing it to slide out.

Fortunately we were clear of the vehicle and the floor jack was under my

control so we didn't drop the Jeep or get anyone trapped. (I only

let Ted jack up the vehicle - lowering it is not as safe and the

floor jack not as easy to control for a kid.) We repositioned the

jack stand under the axle tube. (see photo, left above)

I repeated

this on the passenger side. During the brake install I had to

drain out excess fluid from the brake fluid reservoir because the

calipers were substantially pushed back in due to the increased thickness of the new

rotors and pads.

Once we got everything put back together I

applied the brakes a couple times and then topped up the reservoir with

fresh fluid. Then it was time for a test drive to check for any

problems. But first Ted and I ran over all the jobs making sure

that everything was tightened down properly and that no tools were left

lying in or around the Jeep. We wiped all the areas that had

excess grease, oil, and brake fluid so that we could spot any new leaks

after our drive. We topped up the windshield washer reservoir,

engine oil, and found the power steering fluid was OK.

So we took a ride up

the street to the car wash and rinsed the salt off the vehicle and

chassis.

The afternoon was shot.

We spent about five hours on it including the time to get the parts.

Ted was a real trooper, and might have learned a few things. And

some of our money stayed in our pockets!

Here are a few of the

items we used to do the job, to give you a way to purchase them or

simply to check prices with your local supplier.

xxx

Visitors since

1/27/07