Just what the doctor ordered...

Sometimes you

just have to roll the dice and see what happens. Such was

the case with this Waterloo Tool Drawer full of Miller Special

Tools for the Crossfire . The auction listing said there were a few tools

missing, but if I could get the set at the price I set my limit

to, it would still be an outrageous deal. I got lucky and

"won" the auction at half my bid maximum, which was about what

you'd pay for any one of these special tools! The rollaway

chest alone would be many times more than that. The

factory list price for everything was $6000. Needless to say I was very

happy. Even with the fuel to go pick it up, I was "in" for

less than the cost of the empty tool chest!

So I hit the

road for the 600-mile (round-trip) drive to Ambler, PA.

The seller (Knopf Dodge) measured the case and told me it was

41" x 27" x 18"). Checking the Commander, I found the case

would be a press fit. If the seller rounded down, I would

be "screwed" since I took the whole family and folding down the

middle row of seats would not be an option. I doubled

checked with them and they said yes, that's the correct

dimensions.

When we

arrived, they were very hospitable, even considering they were

closing a family business which was no doubt painful in it's own

way. Not to mention that I basically stole this tool set

for pennies... They were super just the same. I

pulled out the photos that had been on the auction listing and

went through the drawers to make sure that everything was still

there. It checked out and I moved my attention to loading

the chest into the Commander.

We hefted the

case and decided it was too heavy for the two of us to lift

safely. I suggested getting a couple 2 x 4's to use for

ramp and just sliding the whole thing up the 2 x 4's onto the

back of the Commander. The guy that was helping me came

back with two 2 x 4's. While he was looking for them I

remembered they had a car lift in the bays. So when he got

back I suggested we use the car lift. We put the 2 x 4's

on the lift to span the two legs and get us above the little

feet that are adjustable. Then we backed the Commander

into the bay and raised the hoist until the surface of the legs

was level with the inside of the Commander. Then I backed

the Commander in just until the legs were a 1/2 inch from the

floor of the Commander.

Then we simply

put a moving blanket on the edge of the floor on top of the

floor mat that protects the back carpet, and slid the case and

moving blanket into the Commander. Then we hit a small

snag. The wheels on the bottom were too close to the edge

of the opening and prevented the case from going all the way in.

So we removed the wheels, and the case slid right into the

Commander. Done!

I drove back

home with a long detour to downtown Philadelphia and a visit to

Pat's King of Steak - home of the Philly Cheese Steak sandwich.

After being assaulted by some dork in a playground who took

exception to my boy and I going to use the public bathroom (Lots

of yelling - no actual contact) and lunch at Pat's (which was

actually quite disappointing) we got back on the road and headed

home.

When we got

home we hit the sack and then next morning tackled the job of

getting this huge case out of the Commander. Basically I

backed up the Commander to a steep hill, put three planks on the

back bumper as a ramp, slid the case out of the back, then held

the planks up while Maria drove the Commander away. Then I

slid the case down the planks on its back, reinstalled the

wheels, and slid it down the hill on the planks and stood it

back up on pavement. The power of incline planes and

levers!

Here's what the

case looked like before we cleaned and

polished it.

It's a little

hard to tell but the case had a coating of grease on it, the

drawers had thick coats of grease where they had been handled,

and inside more dirt and grease. Perhaps some take pride

in their filthy shop and their filthy tools, but I don't think

my tools have lasted so long from such treatment. I have

never been in a class shop and found filth. We cleaned all

the grease and grime off the outside of the case, cleaned out

all the drawers and all of the tools, and then serviced the

locking mechanism that was a little sticky preventing the

locking action from working smoothly. Here's a view of the

contents after cleaning up and organizing everything into its

place. There's a couple things missing - we'll get them if

it turns out we need them, but for now it's extra space for some

of the spares we have!

Update

11/21/08: I purchased another lot of tools, this time

without the tool chest, and took the tools I was missing to

complete the set. The rest are to be resold.

I had emblems

left from the custom job I did on my center caps so put them on

the tool chest.

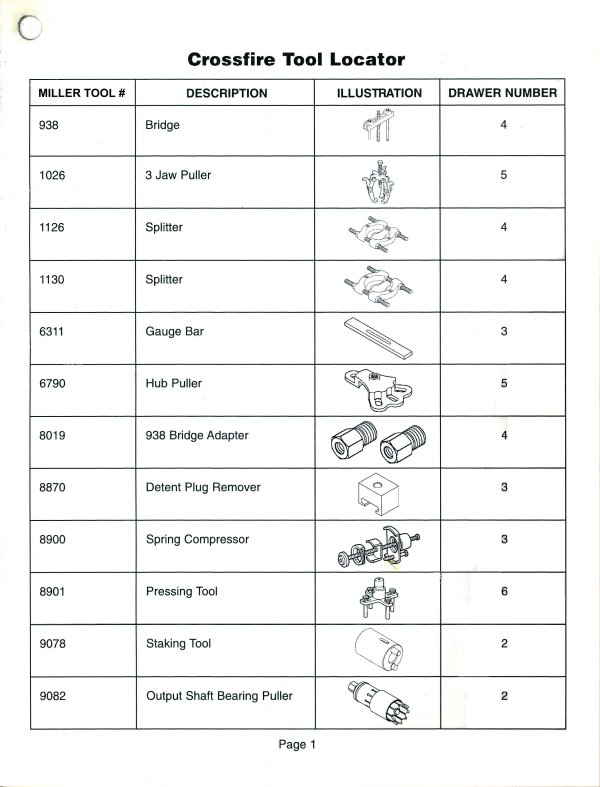

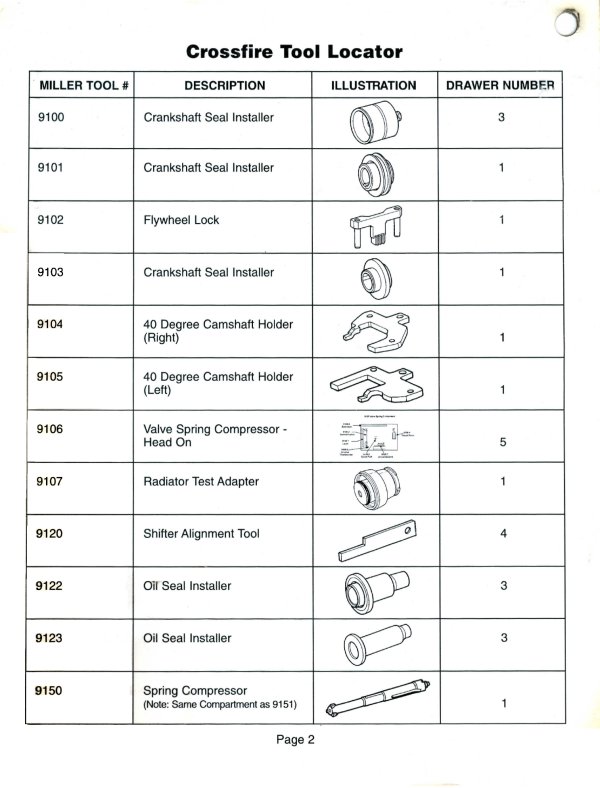

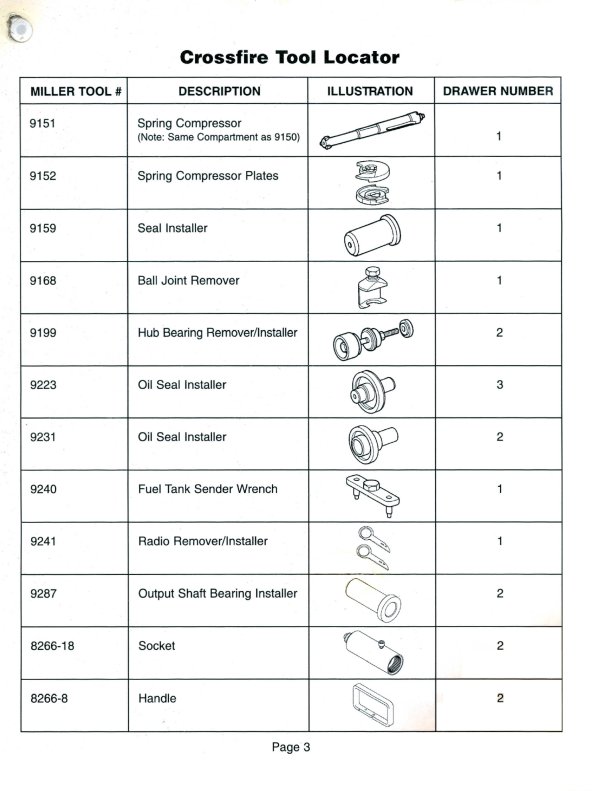

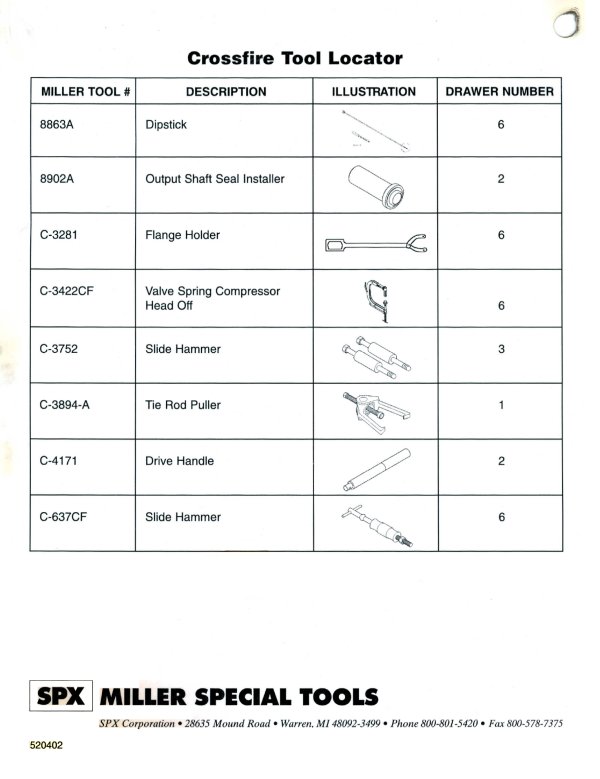

Click Individual Tools

for Detailed Photo

Drawer 1

Click Individual Tools

for Detailed Photo

Drawer 2

Click Individual Tools

for Detailed Photo

Drawer 3

Click Individual Tools

for Detailed Photo

Drawer 4

Click Individual Tools

for Detailed Photo

Drawer 5

Click Individual Tools

for Detailed Photo

Drawer 6

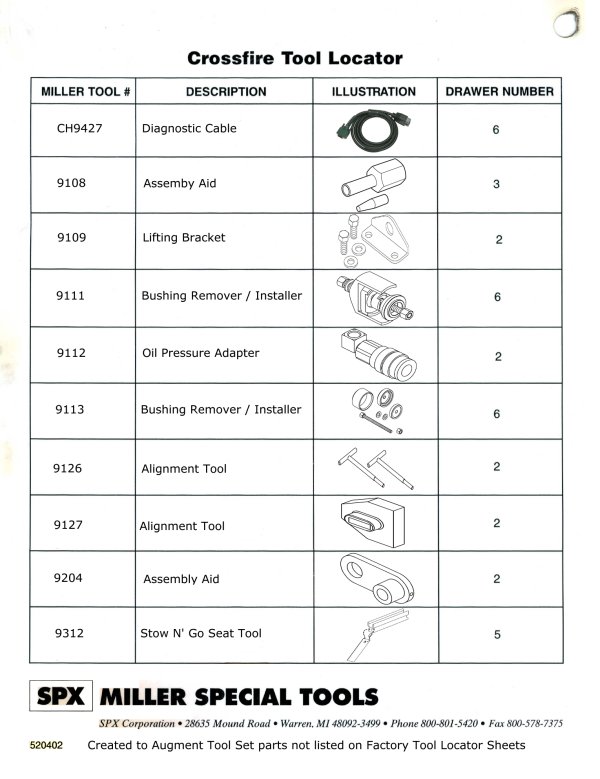

For complete details

of the contents of the tool chest,

click on the Crossfire Tool Locator images below.

I have compiled a detailed listing of the tools and their usage,

and provide a PDF file of this data.

Do I detect a

smile?

Here's some

info about the tool chest itself - this one described below

is wider but essentially the same design.

|

Detail product information for: |

|

|

Series:

|

Traxx ® -

Heavy Use / High

Capacity |

|

Type:

|

Ball-Bearing Tool Cart |

|

Unit #:

|

TRX4106LB |

|

|

All drawers are designed

to accept a second set

of ball-bearing slides

when extra heavy loads

require them |

|

Comes standard with

drawer liners to suspend

tools off drawer bottom |

|

5 x 2-inch (127 x 51mm)

casters with chrome

hubcaps for ease in

maneuvering |

|

Sized to accommodate any

41-inch (1041 mm) or and

26-inch (660 mm) chest |

|

Comes standard with

hardboard worksurface |

|

Tubular side handle |

|

Sidewall post

construction adds

strength in design while

reducing overall weight |

|

Full-extension,

ball-bearing slides for

complete tool access |

|

Equipped with Posi-Latch

drawer securing system

to provide a positive

latch for each drawer

and reduces accidental

opening |

|

Full-width drawers for

storage of long tools |

|

|

|

W

|

D

|

H

|

|

|

Overall:

|

41.0

|

18.1

|

35.6

|

in.

|

|

|

1040

|

459

|

904

|

mm

|

|

|

Overall w/

Casters:

|

41.0

|

18.1

|

41.1

|

in.

|

|

|

1040

|

459

|

1045

|

mm

|

|

|

4 Drawer(s):

|

36.79

|

16.46

|

4.16

|

in.

|

|

|

934.5

|

418.1

|

105.7

|

mm

|

|

|

2 Drawer(s):

|

36.79

|

16.46

|

6.32

|

in.

|

|

|

934.5

|

418.1

|

160.5

|

mm

|

|

|

Capacity

|

Unit Weight

|

Ship Weight

|

|

17731 cu/in.

|

220 lbs.

|

251 lbs.

|

|

290558 cu/cm

|

100 kg

|

114 kg

|

|

capacity - 1200lbs |

|

|

Recommended Accessories

(click name for more detail) |

|

|

Here is a

set of pictures taken by the seller, before we purchased and

cleaned up the set

Visitors since

8/13/08