The lug nuts bear a

side comment. While the factory lug nuts have the more

appealing finish of the stainless-steel cladding on the nut, they

have a tendency to come apart at the most inopportune times.

When they do, the nut underneath is a different size from the lug

wrench. If the cladding happens to get lost, you will find

getting the lug nut off requires using a socket of the correct size

- something you might not have with you on the trail.

After having this

problem a couple times, I purchased some lug nuts at Wal*Mart and

replaced my factory nuts. I figured the solid nut would be

better and I would not have any more problems with lug nuts... All was well until

I was on the

trail and blew out a sidewall. You guessed it - the factory

lug wrench is a different size... Fortunately, I had brought

along my tools and I barely missed a beat. But it got my

attention because I don't always carry my tools.

When I was

swapping

tops and doing all the touch-up work, I took a look at the lugs.

They were trashed. Every time I had new tires put on and every

time I rotated them, an impact wrench was used. I like them

for the speed and ease, but they destroy things like lug nuts.

So next time I go to the tire store I expect not to be very popular

because the impact wrench will not touch my wheels again. As a

matter of fact, I will probably just bring the wheels. That

way there's nothing to discuss. No lugs, no wrench. Period.

I bought the McGard

lugs because the wheel and tire shop I worked in used them with good

results. I know there are probably better ones out there but

these should be fine, nearly double the cost of the Wal*Mart ones,

but perhaps a lot better, and best of all, they're the same size as

the factory ones (3/4" hex nut, 1/2-20 thread).

As

before, I purchased six packages (24 lug nuts) to provide

two spares

that I attach to the spare tire so that they are handy, and so that

the spare has a finished appearance. The part number is 64010

which gets you the 1/2-20 bulge nuts with a 3/4" hex head.

Note this matches the factory lug nuts and will allow the use of the

factory lug wrench.

McGard lug nuts are guaranteed for life.

McGard lug nuts are designed to last for life. They're triple nickel

chrome plated for lasting beauty, and are made of restricted

chemistry steel for structural integrity. All McGard lug nuts are

through-hardened and tempered, reaching the depth of hardness needed

for their unsurpassed level of safety (unlike case-hardening, which

is only a surface treatment). McGard lug nuts also offer a lifetime

guarantee against rust! What more could you ask for?

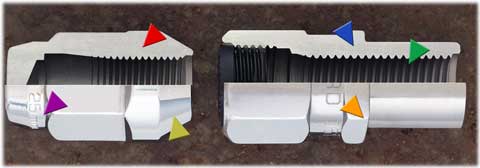

Bulge lug nuts have an extended

seating surface that is designed to match the wider seating surface

used on some aluminum wheels.

McGard employs the same innovative

design and high quality standards used in the production of their

wheel locks in the manufacture of chrome plated lug nuts. The

in-house plating technology and experienced personnel are second to

none in the industry. These capabilities enable McGard to produce

superior quality lug nuts that are strong, safe, durable and exceed

typical corrosion resistance standards. They're so durable in fact

that they are guaranteed for life not to rust, chip, or peel!

McGard is the only manufacturer to

offer 8 different key hex sizes to match the vehicle's original

equipment lug wrench. The user will appreciate this important

feature when they have to change a flat along the roadside.

The McGard process includes three

layers of nickel and one layer of microporous chrome. The first

layer of nickel is for corrosion resistance; the second layer of

nickel is for luster and the third nickel layer interacts with the

microporous chrome layer to disperse nature's corrosive action

(rust)

McGard usees only restricted

chemistry steel, made in the United States specifically for McGard.

These special standards insure the structural integrity of each and

every full machined McGard piece. Every lug nut is through-hardened

and tempered, reaching the depth of hardness needed for its

unsurpassed level of safety (unlike case hardening which is only a

surface treatment).

Core integrity and precision

machining provide the highest strength in the industry. All McGard

locks and lug nuts meet or exceed the highest OEM proof load

standards, 135,000 to 160,000 PSI.

McGard's standard for

concentricity of the bearing surface to the pitch diameter is 30%

more precise than OEM standards. This insures even distribution of

the clamp load and uniform seating of the lock to the wheel.

Visitors since

5/30/07