Installation

The

installation of this group of components

is extremely challenging.

There are many connections to the car

wiring harness. Additionally,

there are several components that make

up this functional unit so there are a

number of connections just to configure

the basic boxes and display. And there

are some things that are not documented

in the owners and installation guides...

I did not get much satisfaction calling

and writing to Pioneer. The web

site support responds by saying I need

to call. Then the person I talk to

when I call reads the manual to me...

Bench Testing

Make no

mistake - without the very detailed

wiring and installation plans, a clean, organized

installation of this many components, with

this many wires and connections, success

would be at risk, and troubleshooting nearly

impossible. So if you have just

glossed over the wire diagrams, comments

about RPM calibration, coils, power and so

on, and think you can just grab your boxes

and run out to the car - stop!

I had the

benefit of assembling the circuit diagram

from all the sources (factory service

manual, navigation radio installation

manual, Pioneer component installation

guides, and the MSD interface guide, I feel

ready. That right there is almost 20

hours of "studying".

I am still not

ready to get into the car. First I

decided to assemble the units on the bench.

This required the purchase of a 120 volt to

12 volt converter. Don't go buy a

dinky one at WalMart. Those are made

for powering little devices with 100-300ma

power requirements (that's no more than a

third of an amp). The Pioneer devices take

as much as two amps each. Just for fun

I tried to power them using a 300ma converter. Nothing

worked. Not enough power.

I purchased

a unit meant to power small 12v cooler that

puts out six amps continuously. Watch

out for some units for sale that only put

out a rated amperage for a short time.

You may want more test time than the unit

can be run! Here's the one I got.

A good compromise between price and power

output, with 100% duty cycle (that means it

can run continuously).

With this

device, I had a suitable test set up and I

was ready to start putting things together.

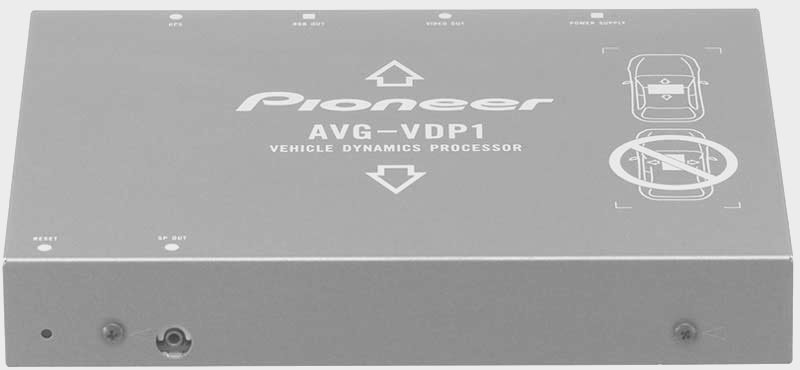

First I

assembled the control units to their

respective devices - the AVG-VDP1 to the

AVD-W63210 Hide-Away unit.

Next I put

connectors on all the wires. With

these basic steps done it was time to test

for basic operation of the display and

processor.

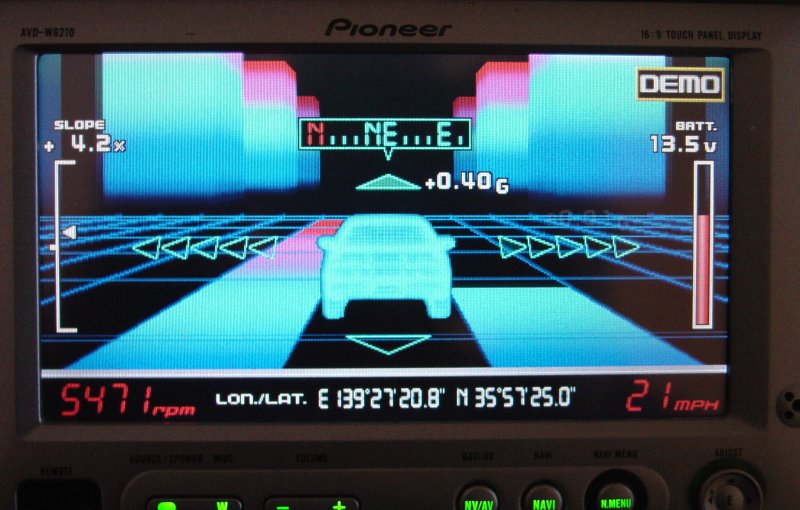

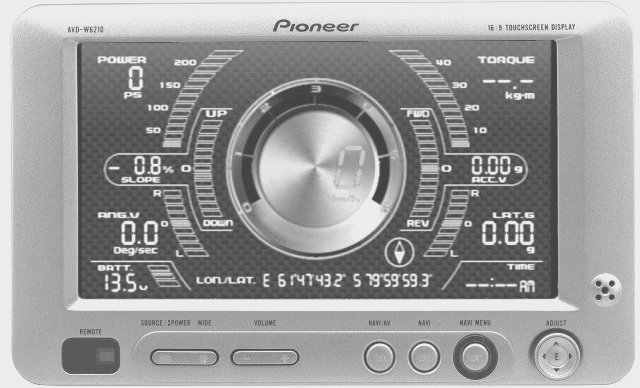

I was happy to

find that the display powered up and the

AVG-VDP1 ran through it's start-up screens.

The menus all worked and the GPS soon

acquired several satellites (with the

satellite antenna placed outside with open

sky above it. Since the live screens

were pretty dull because the unit was not

moving, here are some of the demo screens

that to photographed on the bench.

With these

basics out of the way I knew that the boxes

and display work and I moved my attention

to the car. It needs to have wiring

harnesses fitted, connection points selected, clean harness extensions, and connectors

put in place. That kept me busy for a

a few hours...

Monitor Installation

I chose to install

the touch-screen monitor on my existing Panavise bracket that

holds my GPS, radar detector and BassLink Remotes. I was

necessary to add an extension bracket, reinforce it with a short

piece of aluminum angle-stock, modify the swivel head so the

monitor would remain close to the bracket, and to manage some

wires. With this out of the way (no small task as the

bracket parts had to be custom made and hardware to fit

purchased and tested. While the end result is by no means

pretty, it does allow the glove compartment to be opened easily,

and does not wobble around or obscure the view through the front

window.

Speed and Reverse Signals

I relied

heavily on the factory service

manual for the Crossfire (to understand

the various control modules in the car,

the location and ratings of various

signal sources; the installation guide

for the Crossfire factory navigation

radio (provides the best connection

locations for the Speed signal and

Reverse Switch controls).

The drawing that

follows comes from the Crossfire Factory Installation Guide for

the Factory Navigation Radio. It shows the location of the

Speed Signal and (if you like it) the reverse signal. This

is how Chrysler recommends making these connections.

Here's an

alternative to the reverse signal that I opted to use. I

didn't want to cut into the harness shown in the drawing.

It was just too neat and tidy to start hacking into. But

what really convinced me to go another route was the fact that

the lead would have to run the length of the car to the

components in the rear. Why not just use the reverse lamp

lead in the back of the car and have a short run to the

component?

It's the 12-volt

lead to the lamp (Gray/Yellow) wire that connects pin 5 on

either the right or left rear lamp assembly, concealed behind a

removable panel. I found it easy to snake the wire up

behind the interior trim panel from below and attach using the

same approach shown in the splicing illustrations above. I

added a connector to the new piece of wire so that I could later

remove the lead without unsoldering the lead.

RPM

Signal

The most

challenging part of this installation is

the identification of a suitable power

source for the ignition-controlled 12v

lead. The issue is that this unit

uses vehicle engine RPM as a key

component of data in its calculation of

the various outputs. Without an

accurate RPM reading, the unit is

useless.

It may not

seem a very tough thing. Indeed,

at first I read the manual and saw only

12v leads for continuous (battery) power

and switched power. But then

thinking about my Pioneer DEH-P980BT and

the Vehicle Dynamics it offers, I

recalled that the RPM calibration

doesn't work. I got to thinking

about this and got on the web. And

it didn't take long before I discovered

a dirty little secret about this device

- many people have been unable to

calibrate RPM's and so the unit is

practically useless to them. I was

determined to figure out what almost everyone else had missed

(including the support line at Pioneer...).

The

problem for all of them is simple -

newer cars use breakerless, electronic

ignition. These vehicles have a

coil bank or coils for each spark plug.

Additionally, these cars (and the

Crossfire has gone to great length here)

have very elaborate noise-suppression

circuits to prevent ignition noise from

being transmitted through audio systems

and other entertainment systems that

have speakers. The "noise" that it

is suppressing is the waveform that the

Pioneer AVG-VDP1 uses to detect engine

revolutions! So in short, modern

electronic ignition such as that found

in the Chrysler Crossfire prevents the

device from working if it is wired like

a stereo.

I went

through a lot of trouble to isolate my

power for my stereo so that it would not

transmit noise. So connecting this

device to my stereo power sources was a

non-starter. But what was I to do?

There had to be somebody who figured out

how to get around it for their car.

After

several hours of drilling into searches

I finally found a single post from a

person in Australia who described a way

to wire the unit to overcome the

problem. Essentially, the power

sources are taken from one of the

sparkplug coils and isolated from the

battery using small diodes. This

approach would work for some vehicles but not the Crossfire.

I reproduced it here for those who are looking for a solution.

I drew

it out below. In actual practice,

though I did install this wiring

initially, I removed it because in the

end, I found another solution that was

less complex and very reliable. I

have left this drawing but be advised it

is not applicable to the Chrysler

Crossfire. Read on.

This lead

me to stop and consider what I was

getting myself into. And I decided

it would be best if I cracked open the

factory service manual for the car and

identify all the connection points ahead

of time so that during installation, I

would not have to go back and forth from

the manual to the car a million times.

I ended up drawing a very detailed

wiring diagram (included) and in

the process reached the conclusion that

I was going to have to solve the RPM

calibration issue or give up on the unit

altogether. So I got busy doing my

research and after about 3 hours found a product that answered the

mail. I should add that in the

course of two phone calls and one email

to Pioneer Support they had no clue

and

could not tell me anything about this

detail. That's what they get for

outsourcing their support center...

What I found is a Tach Signal GMR

Pickup from MSD.

It works

by detecting the signal going to the

coil pack on the spark plug, then converting a 12v input

to something the RPM detector in the

AVG-VDP1 can

calibrate to. For my application

that means attaching the tach signal

pickup to one of the coil pack positive

leads.

The MSD GMR pickup

can be used with inductive or capacitive

ignition types to provide an rpm signal

of 30% duration when the ignition coil

fires. Two washers are provided with the

pickup and must be installed in one of

two positions depending on the type of

ignition driving the coil.

Here is

the wiring diagram from MSD:

Click the image above for the

Installation Manual

MSD Installation

Here's the

information from the factory service

manual regarding the coil pack on the

engine. The MSD device simply

clips onto one of the positive coil pack

input leads. One lead goes to

ground, another to the switched 12v

positive power source, and the last goes

to the wiring of the AVG-VDP1 as the

Switched Accessory Lead.

The

instructions below are provided to give

a sense of where the coil packs are

located and how to reach them, do not

continue past step 2 since it is

unnecessary to remove them. Just

familiarize yourself with the

location and then install the

MSD unit according to the

instructions provided with the

unit. It took me more time

to remove and replace the air

filter cover than to attach the

clip to my cylinder number six

coil 12-volt input lead...

Switch Gear

After careful

consideration, I decided to install the

switches on the panel that surrounds the

stick shift. I managed to find two

switches that have a similar form factor to

the side-view mirror knob.

(switches below

are similar but with round instead of square edges)

Carefully

measuring to make sure the structure of the

panel would not be damaged, and to assure

the space behind the panel was deep enough

to allow switches, I marked the switch

locations - carefully lined up with the

window switches, and parallel to each other.

With no going

back, I drilled the holes needed (with a

center punch mark, small pilot hole then a honking 15/16"

speed-bore) to install

the switches. This was the only point

in the entire installation where I felt there was no going back.

One slip of the drill and this highly visible piece of interior

would be toast. There is no hiding a misplaced one inch

hole...

I was able to make the

holes exactly where I wanted them, and the

switches fit as planned. While they

are not silver and do not match the window

switches, I feel they are consistent with

the side view mirror control on the same

console so do not appear too out of place.

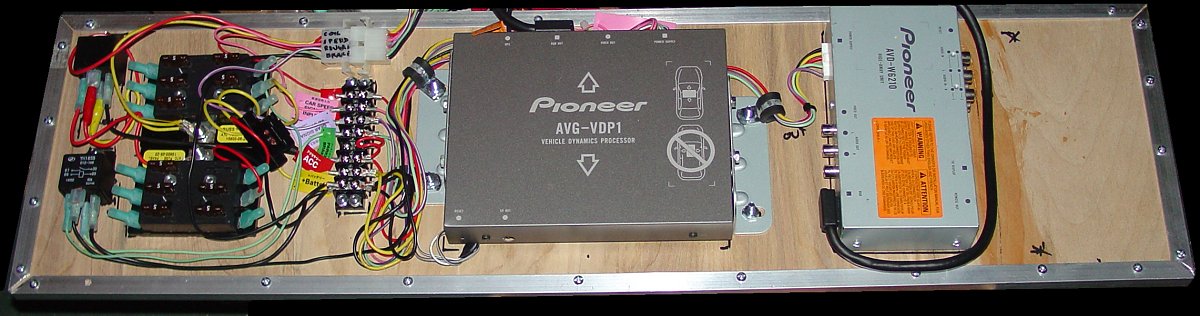

Component Construction

I

previously constructed a storage compartment

by creating a four-inch deep insert that

goes into the cargo area. I fabricated

a heavy-duty cover and carpeted it to match

the car. To this I attached my

sub-woofer. The compartment is not

easily detectible. Here it is with the

compartment closed. Not much to see, huh?

Here it is shown

open. Some of the contents were

removed to leave an empty compartment to hold the component

board and harness.

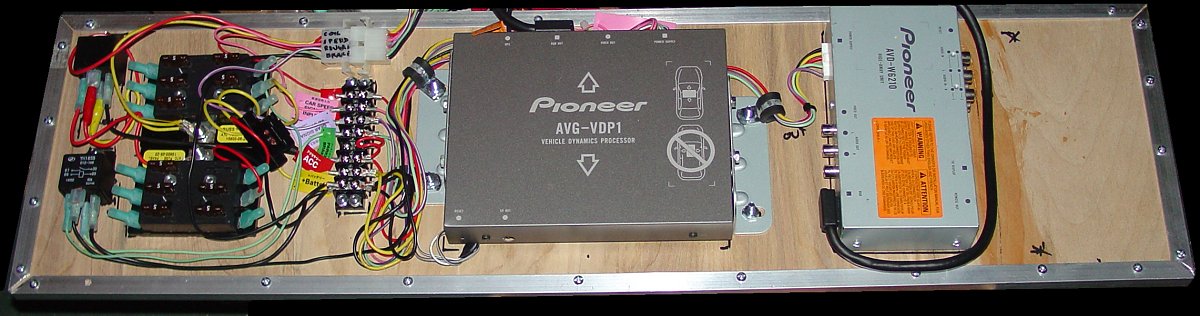

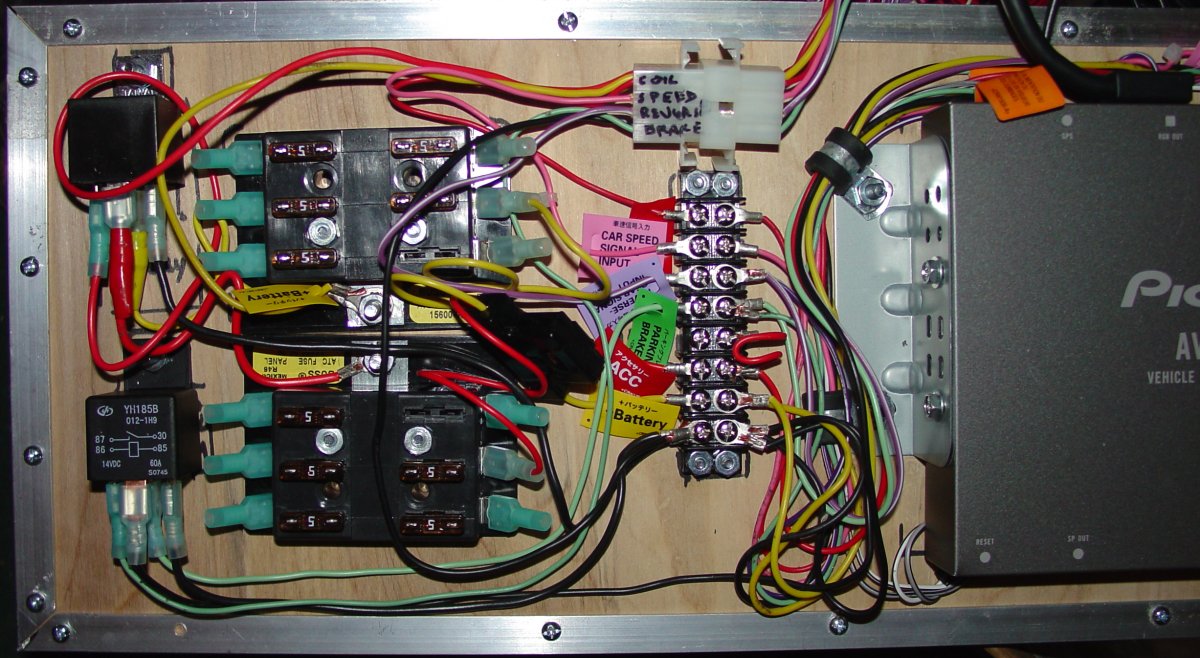

For this set

of components, I took a 1/4" piece of finish

quality birch plywood. I laid out the

parts as described in the wiring plan above.

Then I attached the components to the panel.

I left some room on the right for the

rear-view camera control box (I can dream,

can't I?) and space between the components

for airflow and wiring.

Using a

variety of small hardware fasteners, I

anchored all the pieces to the panel.

Then I added a border on the panel to give

it rigidity, and to raise it up slightly off

the floor of the compartment.

In order to be

sure it would be easy to remove the

components, I created a harness for the

leads that go to various parts of the car,

isolating the board and components so that

only the harness connector need be separated

to remove the entire unit. This is

necessary because the tire repair and

jacking equipment lie under the compartment.

Cooling and Monitoring

Realizing the

compartment with the components will get

warm, I installed a small indoor/outdoor

thermometer that gives me the temperature

inside the cabinet, and in the car.

This allows me to monitor the temperature.

Since the wire was not long enough to reach

the dash and be concealed, I placed the

thermometer inside the console compartment

where I can refer to it as needed. The

side bonus is that the console compartment

contains the iPod so I can see if things are

getting too hot there as well. It's

all good...

After monitoring temperatures in

the compartment I found that the units do not produce much heat.

The temperature inside the compartment is only a couple degrees

higher than the temperature outside the compartment.

Still, in the dead of summer when the sun hits the black carpet

through the big hatch window, I am sure there will be plenty of

heat and some air flow will be necessary to preserve the life

and reliability of these electronics.

To keep the

components cool, I added a few vents on the

enclosure and installed a cabinet fan.

|

|

|

Dimensions |

| |

|

Product Length

|

|

1.57

|

|

|

Product Height

|

|

0.39

|

|

Product Width

|

|

1.57

|

|

General Features |

| |

|

Model

|

|

273-240

|

|

|

Product Type

|

|

Standard case fans

|

|

|

Recommended Use

|

|

Computer Builder

|

|

|

Body Material

|

|

Multi

|

|

|

Fits What |

| |

|

Model

|

|

273-240

|

|

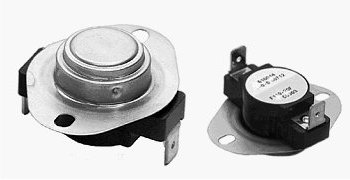

To control the fan I added a thermal switch

that comes on at 115 degrees and shuts off

at 90 degrees. I added a warning light to inform

me that the compartment is above 115 and that the fan is

(supposed to be) on. This gives a fan

that self regulates and a monitoring indicator to let me know

when it's coming on. A quick test of the completed circuit

using the bottom of a cup of hot coffee to activate the switch

confirmed that it comes on and shuts off in the desired

temperature range.

It will probably run most of the time

on short trips on hot summer days (my inside thermometer

routinely pushes past 100°) but potentially could get the

component compartment cooled

on longer trips because the air conditioning will eventually get

the passenger compartment cooled and the fan will pass that

cooler air through the compartment. So far on cold winter

days, even for long rides, the component compartment does not

get any warmer than the main cabin. This suggests that the

components do not generate much heat, and indeed, none of the

installation materials make any special comment about airflow or

the need to cool the devices. Still it never hurts to keep

electronic component temperatures under control.

|

Red LED with Holder

Model: 276-270 | Catalog #: 276-270 |

- Mfg hole

diameter is 9/32

- Typical

Voltage: 12, with a maximum voltage of 16V

- Typical MCD:

33

- Typical

wavelength: 635nm

- Viewing angle:

25XXX°

- 15mA (max)

|

|

The fan, LED, and thermal switch were

not installed at the time I took the pictures.

Component Panel

The finished

product is workmanlike, not something to

open up and show off at a car show.

That's not what I made it for. I just

wanted the parts to be anchored down, easy

to move as a unit, and with as few wires as

possible. I could have spent a lot

more money and time to make it pretty -

maybe someday...

Install Comments

Once you break

down the job into identifying the components, planning out and

executing the wiring sub-assemblies, installation is really not

much more than placing the finished component board into the

space you set aside for it (in my case a hidden compartment in

the rear hatch area) and then running wires to the connection

points, connecting the wires, then concealing them. I

added a couple switches to the mix, which required drilling out

the console. And I added the MSD sending unit for the RPM

signal, which acts as the 12-volt switched lead. But

really installing this in the car after all that, was just about running the

wires and plugging in the connector I made.

Here's an

evaluation of the installed

unit...

Overview |

Components |

Wiring | Installation |

Evaluation

Visitors since

12/31/08